Kanban Board

What is Kanban Board?

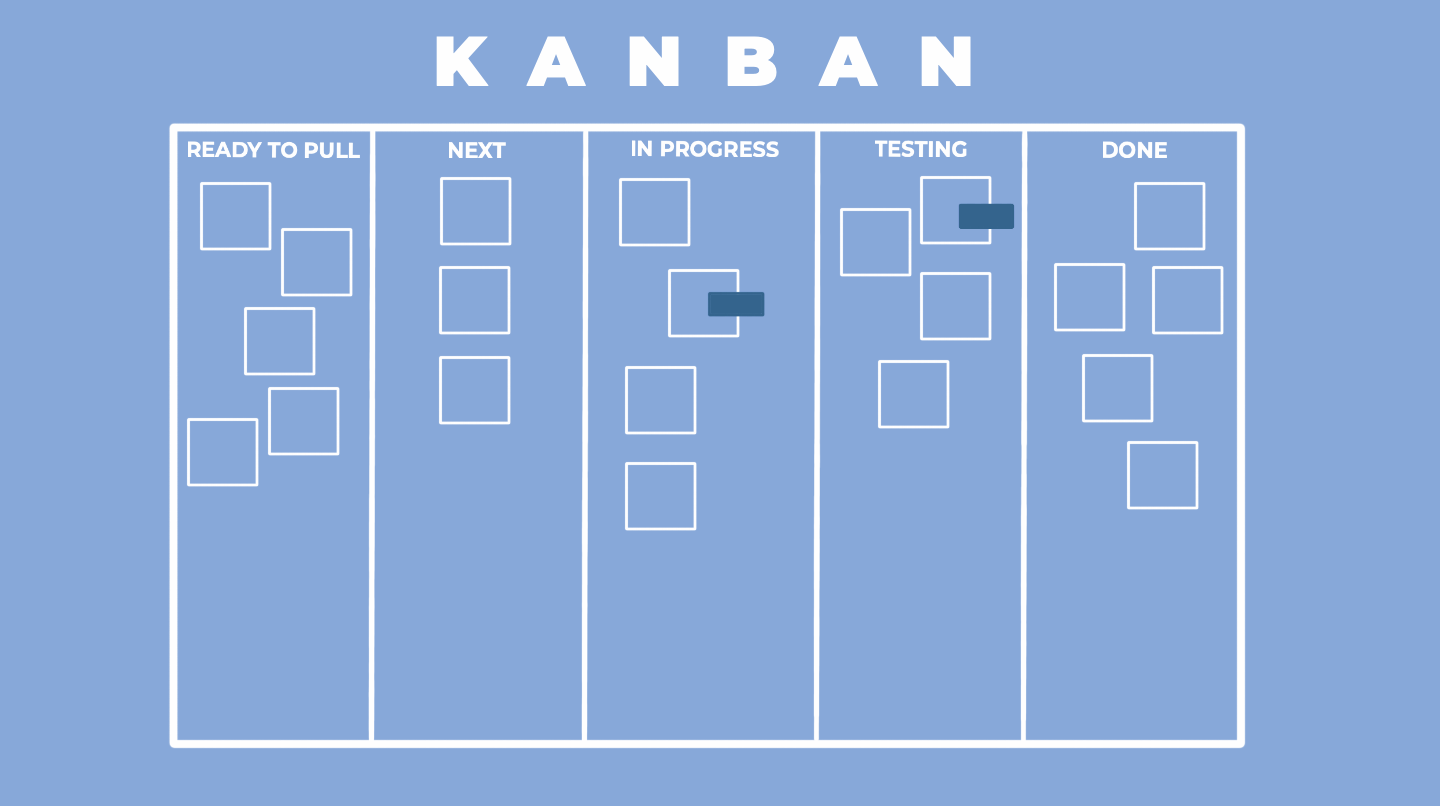

Kanban Project Management Visual Cues This methodology seeks to fantasize the workflow and identify implicit backups, therefore perfecting the performance. Kanban Board The first and most egregious cue is a Kanban board. Its thing is to fantasize the workflow, limit work in progress, and increase effectiveness. These boards can be either physical or digital.

What are the main components in Kanban Board?

DavidJ. Anderson, a colonist in the Kanban field, broke down the board into five main components. The Five Factors of Kanban Visual signals — Signals can be cards, stickers, tickets, or anything differently that the platoon can use to write their systems and work particulars. This way, other teammates and stakeholders can fluently understand what’s on the board.

Columns — Each column on the Kanban board represents a different exertion in the workflow. The platoon will determine the number of columns they need to represent their design meetly. The simplest type of board can have three columns marked “to do,” “work in progress,” and “finished.

Work-in- Progress limits — WIP limits serve to establish the maximum number of cards that can appear on each column. However, no further than five cards can be placed in it, If the WIP limit column is marked with five. This way, the platoon must concentrate on the cards that are formerly on the board and move them to the coming stage before adding further. That’s an excellent way to spot backups and ameliorate the workflow. Likewise, limits can also show if the platoon committed too important to a specific part of the project.

A commitment point — brigades frequently use a backlog for the board where guests and platoon members can place ideas that the platoon can pick up as soon as they’re available. The commitment point is the moment when the platoon picks up the idea and starts working on the project.

Delivery point — The delivery point is the final stage of the design, and for utmost brigades, it’s the moment when the design is in the hands of the customer or client. The platoon’s thing is to move cards across the board to the delivery point as soon as possible. The time it takes for a card to travel from the commitment point to the delivery point is also known as super eminent time.

Cards Even in the morning, cards played an essential part in this specific system. They served as a signal to show when the company should move accoutrements within the installation. In substance, the cards were used as a signal that the company was running out of corridor, accoutrements, or items. These cards generally offer precious information about a specific item. That can include the name of the person in charge, the deadline, task summary, etc.

The main thing of Kanban cards is to Act as an information mecca, Exclude the need for factual meetings, Demonstrate translucency of the project. Similar traits work for both physical and digital cards. Moment, you won’t find numerous physical bones since software- grounded on Kanban can offer so much more.

These digital cards can show the person assigned to the task, cycle time, and any implicit subtask. Moreover, teammates can add commentary, lines, external links, and anything differently. That results in better communication between the platoon members and inspires collaboration.

Swim lanes represent a form of grading and tracking different tasks. Generally, they’re represented by a vertical line that divides the board into two or further parts. One of the main uses of swim lanes is to separate colorful types of content (e.g., textbook and videotape). The upper part of the board can serve for textbook, while the bottom one is for videotape. Since these two orders are non-sequential and different in nature, the platoon will separate them to allow easier following and a betterflow. It might also be a good idea to add WIP limits to both categories. The most common types of swim lanes are Individual — If the company is looking to fantasize the work of different brigades or individualities. The same can apply for multiple guests if the platoon is working on several systems at the same time. Repetitive tasks — Creating a special swim lane for repetitive tasks might be an exceptional idea.

This is common in IT, where a platoon has to conduct regular conservation, for example.

Classes of service — The platoon can add multiple swim lanes grounded on the precedence of each task. However, they can put it in its own swim lane to separate it from the rest of the design, If they’ve a low- precedence task.

Company- position — For everyone looking to produce a board for the entire company where they can follow colorful strategic objects, crucial results, and teams.

Discarded options — Since utmost systems are fluent, brigades can frequently discard an idea. Rather of just “throwing it down,” the platoon can add a swim lane for discarded options in case they prove to be better than the alternative.

Business Analyst , Functional Consultant, Provide Training on Business Analysis and SDLC Methodologies.